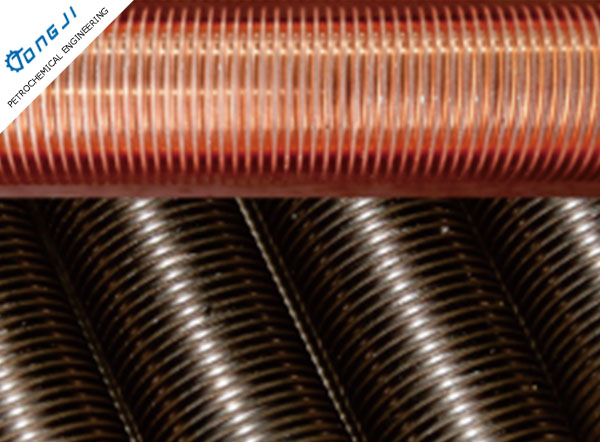

TONGJI-INTEGRAL LOW FIN TUBE is available for a wider range of alloys than traditional low-fin tubing which is restricted to soft metals. Such as Titanium , Nickel Alloy, Duplex Steel.

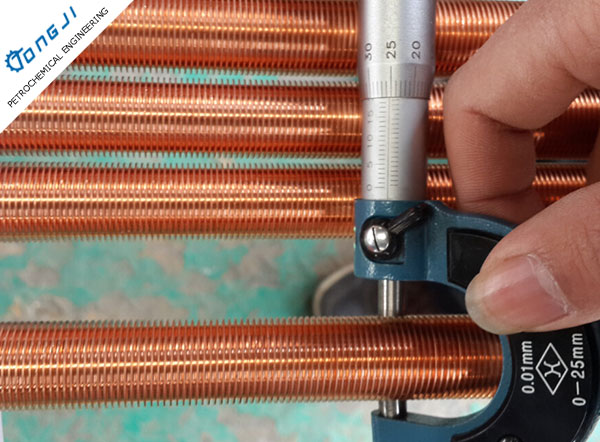

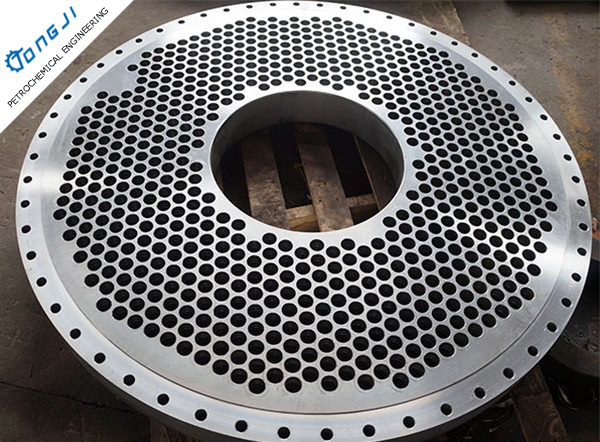

The integral low fin tubes are from extruded seamless tubes on outside surface only or outside and inside surface for double enhanced performance.

Material: Copper, Stainless Steel, Duplex, Titanium, Nickel Alloys, Copper Nickel (90/10,70/30)

Our low fin tubes are available for a wider range of alloys Such as Copper ,Titanium , Nickel Alloy, Duplex Steel.

ASTM A-1012 Seamless and Welded Ferritic, Austenitic and Duplex Alloy Steel Condenser And Heat Exchanger Tubes with Integral Fins.

ASTM B-891 Seamless and welded Titanium and Titanium Alloy Condenser and Heat Exchanger Tubes With Integral Fins

ASTM B-924 Seamless and Welded Nickel Alloy Condenser and Heat Exchanger Tubes With Integral Fins

ASTM B-359/ ASME SB-359 Copper and Copper Alloy Seamless Condenser and Heat Exchanger Tubes With Integral Fins

Size Range: OD 1/2” to OD 1”

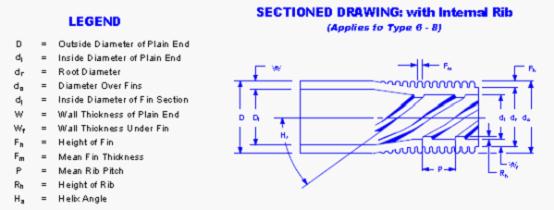

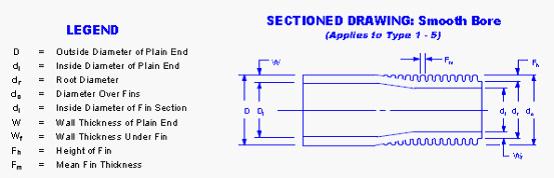

Type: Smooth Bore or Internal Rib

FPI: 19,26,28,36 etc as per your customer’ request

Test: Air test at 250Psi(1.72 Mpa),Hydro Test

Benefits:

Enlarged the external surface area of bare tubes by 2.5 to 3 times & Improved Heat transfer

Reduced capital cost for the new facility

Reduced refitting cost for the existing facility

Saved space, weight and structure in offshore production or high elevation distillation

Transform large shell & tube exchangers into compact heat exchangers

Copper, Stainless Steel, Duplex, Titanium, Nickel Alloys, Copper Nickel (90/10,70/30)

Enlarged the external surface area of bare tubes by 2.5 to 3 times & Improved Heat transfer

Reduced capital cost for the new facility

Reduced refitting cost for the existing facility

Saved space, weight and structure in offshore production or high elevation distillation

Transform large shell & tube exchangers into compact heat exchangers